-

-

Product

-

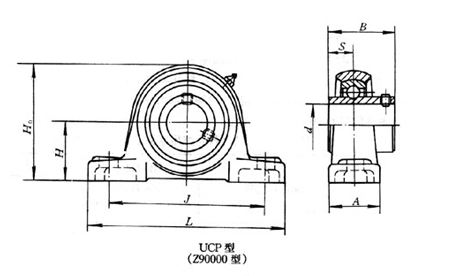

UCP310 NSK Pillow Block Bearing

Compared with other ordinary bearings, outer spherical ball bearings have another feature: double sealing, because the use of outer spherical ball bearings is generally harsh environmental conditions, especially agricultural machinery bearings, and double sealing ensures that dust is not easy to enter the inside of the channel. In the last two years, some companies have developed three-lip sealed outer spherical bearings, which greatly strengthen the dustproof ability. The service life of the bearing is extended.

Category:

Pillow Block Bearing

WhatsApp:+8613585510566

Email:sales@rm-bearing.com

Message

Product Description

Bearing seal:

Compared with other ordinary bearings, outer spherical ball bearings have another feature: double sealing, because the use of outer spherical ball bearings is generally harsh environmental conditions, especially agricultural machinery bearings, and double sealing ensures that dust is not easy to enter the inside of the channel. In the last two years, some companies have developed three-lip sealed outer spherical bearings, which greatly strengthen the dustproof ability. The service life of the bearing is extended.

Pillow block bearing , namely outer spherical bearings. It belongs to the deep groove ball bearing, inside the rolling body for the steel ball; Its outer ring surface is spherical, so it is called pillow block bearing.

Pillow block bearing with seats are usually with bolts, which are convenient to be fixed in the place where they should be fixed. There are also slider type and frame type, which are fixed by clamping, and overhang type and suspension type, which are usually with threads, which are convenient to be fixed in the rod end or suspended in the air.

At the same time, this kind of bearing is also designed with a certain centrality, easy to install, with a double structure of sealing device, can work in harsh environment. The bearing seat is generally molded by casting. Commonly used seat is vertical seat (P), square seat (F), boss square seat (FS), boss round seat (FC), diamond seat (FL), ring seat (C), slide block seat (T).

What are pillow block bearings made of?

Material. Pillow Block Bearings is usually made of aluminum that offers high loading carrying capacity and heat conductivity. On the other hand, pressed steel is used in low load carrying applications yet it offers high performance with precision. Stainless steel is used because of its ability of corrosion resistance.

A pillow block bearing is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing. The block is mounted to a foundation and a shaft is inserted allowing the inner part of the bearing / shaft to rotate. The inside of the bearing is typically 0.025 millimetres (0.001 in) larger diameter than the shaft to ensure a tight fit.set screws,locking collars , or set collars are commonly used to secure the shaft. Housing material for a pillow block is typically made of cast iron or cast steel.

A pillow block may contain a bearing with one of several types of rolling elements, including ball, cylindrical roller, spherical roller, tapered roller, or metallic or synthetic bushing. The type of rolling element defines the type of pillow block.

RELATED PRODUCTS

MESSAGE

Contact

Phone:+8613585510566

Email:sales@rm-bearing.com

WhatsApp No:+8613585510566

Wechat No:13585510566

Address:63 Liantai Road, Baoshan District, Shanghai

©2023 Shanghai Ruomi Bearing Co., Ltd. SEO Business License